Security News

Research

Data Theft Repackaged: A Case Study in Malicious Wrapper Packages on npm

The Socket Research Team breaks down a malicious wrapper package that uses obfuscation to harvest credentials and exfiltrate sensitive data.

A library to interface with the opentherm gateway through serial or network connection.

A python library to interface with the OpenTherm Gateway

See http://otgw.tclcode.com for the hardware.

This library is written primarily for use with Home Assistant (https://www.home-assistant.io) but can be used for other purposes as well. Parts of the code have not been thoroughly tested since my thermostat and boiler do not support all OpenTherm features. Feel free to test and contribute where you see fit.

pyotgw exposes its OpenThermGateway class which uses pyserial-asyncio to connect to the OpenTherm Gateway.

After initialization of the object, OpenThermGateway.connect() should be used to establish a connection. The object will maintain the connection in the background, using it to send commands and continuously receive updates. The received information will be cached on the object for instant availability.

The OpenThermGateway object implements a watchdog to monitor the connection for inactivity. During OpenThermGateway.connect(), an inactivity timeout can be set for this purpose. Normally, the OpenTherm Gateway will send a message on its serial interface approximately every second. If no messages are received for the duration of the timeout, the watchdog will trigger a reconnection attempt.

There are multiple ways to get information from pyotgw. Calling OpenThermGateway.connect() will request some initial information from the Gateway and return it in a dict. After this, the OpenThermGateway object exposes quite a few methods which return values that are cached on the object. There is also the option to register a callback with OpenThermGateway.subscribe() which will be called when any value changes.

The OpenThermGateway constructor takes no arguments and returns an empty OpenThermGateway object.

Add the specified data-ID to the list of alternative commands to send to the boiler instead of a data-ID that is known to be unsupported by the boiler. Alternative data-IDs will always be sent to the boiler in a Read-Data request message with the data-value set to zero. The table of alternative data-IDs is stored in non-volatile memory so it will persist even if the gateway has been powered off. This method supports the following arguments:

Returns the ID that was added to the list, or None on failure.

This method is a coroutine.

Inform the gateway that the boiler doesn't support the specified data-ID, even if the boiler doesn't indicate that by returning an unknown-dataID response.

Using this command allows the gateway to send an alternative data-ID to the boiler instead.

This method supports the following arguments:

Returns the added ID, or None on failure.

This method is a coroutine.

Connect to an OpenTherm Gateway and initializes the parameters obtained from the PS and PR commands.

If called while connected, reconnect to the gateway.

All optional serial-related arguments default to the OpenTherm Gateway default settings.

This method supports the following arguments:

Returns a status dict with all known values.

This method is a coroutine.

Disconnect from the OpenTherm Gateway and clean up the object.

This method is a coroutine.

Remove the specified data-ID from the list of alternative commands. Only one occurrence is deleted. If the data-ID appears multiple times in the list of alternative commands, this command must be repeated to delete all occurrences. The table of alternative data-IDs is stored in non-volatile memory so it will persist even if the gateway has been powered off. This method supports the following arguments:

Returns the ID that was removed from the list, or None on failure.

This method is a coroutine.

Start forwarding the specified Data-ID to the boiler again. This command resets the counter used to determine if the specified data-ID is supported by the boiler. This method supports the following arguments:

Return the ID that was marked as supported, or None on failure.

This method is a coroutine.

Update the OpenThermGateway object with the information from all of the PR commands.

This method is also called from OpenThermGateway.connect() to populate the status dict with initial values.

Returns the full updated status dict.

This method is a coroutine.

Update the OpenThermGateway object with the information from the PS command.

This method is also called from OpenThermGateway.connect() to populate the status dict with initial values.

Returns the full updated status dict.

This method is a coroutine.

Set or unset the Central Heating Enable bit.

Control the CH enable status bit when overriding the control setpoint. By default the CH enable bit is set after a call to OpenThermGateway.set_control_setpoint() with a value other than 0. With this method, the bit can be manipulated.

This method supports the following arguments:

Central Heating Enable bit. Can be either 0 or 1.Return the newly accepted value (0 or 1), or None on failure.

This method is a coroutine.

Set or unset the Central Heating Enable bit for heating circuit 2.

Control the CH enable status bit when overriding the control setpoint. By default the CH enable bit is set after a call to OpenThermGateway.set_control_setpoint() with a value other than 0. With this method, the bit can be manipulated.

This method supports the following arguments:

Central Heating Enable bit. Can be either 0 or 1.Return the newly accepted value (0 or 1), or None on failure.

This method is a coroutine.

Set the clock on the thermostat. Change the time and day of the week of the thermostat. The gateway will send the specified time and day of the week in response to the next time and date message from the thermostat. This method supports the following arguments:

datetime.now().Returns the accepted response from the gateway with format HH:MM/DOW, where DOW is a single digit: 1=Monday, 7=Sunday, or None on failure.

This method is a coroutine.

Set the serial connection parameters before calling connect(). Valid kwargs are 'baudrate', 'bytesize', 'parity' and 'stopbits'. Returns True on success, False on fail or if already connected. For more information on the kwargs see the pyserial documentation.

Set the control setpoint.

The control setpoint is the target temperature for the water in the central heating system. This method will cause the OpenTherm Gateway to manipulate the control setpoint which is sent to the boiler. Set the control setpoint to 0 to pass along the value specified by the thermostat.

This method supports the following arguments:

Returns the newly accepted value, or None on failure.

This method is a coroutine.

Set the control setpoint for central heating circuit 2.

The control setpoint is the target temperature for the water in the central heating system. This method will cause the OpenTherm Gateway to manipulate the control setpoint which is sent to the boiler. Set the control setpoint to 0 to pass along the value specified by the thermostat.

This method supports the following arguments:

Returns the newly accepted value, or None on failure.

This method is a coroutine.

Set the domestic hot water setpoint. The domestic hot water setpoint is the target temperature for the hot water system. Not all boilers support this command. This method supports the following arguments:

Returns the newly accepted setpoint, or None on failure.

This method is a coroutine.

Configure the functions of the two GPIO pins of the gateway. Possible modes are:

This method supports the following arguments:

A or B.0 to 7 are supported (7 only for GPIO B).Returns the new mode for the specified gpio, or None on failure.

This method is a coroutine.

Control the domestic hot water enable option.

If the boiler has been configured to let the room unit control when to keep a small amount of water preheated, this option can influence that. A state of 0 or 1 will override the domestic hot water option off or on respectively. Any other single character disables the override and resumes normal operation.

This method supports the following arguments:

Returns the accepted value, A if the override is disabled or None on failure.

This method is a coroutine.

Set the mode of one of the LEDs. Configure the functions of the six LEDs (A-F) that can optionally be connected to pins RB3/RB4/RB6/RB7 and the GPIO pins of the PIC. Possible modes are:

This method supports the following arguments:

A-F.R, X, T, B, O, F, H, W, C, E, M or P.Returns the new mode for the specified LED, or None on failure.

This method is a coroutine.

Set the maximum central heating water setpoint. Not all boilers support this option.

This method supports the following arguments:

Returns the newly accepted setpoint, or None on failure.

This method is a coroutine.

Set the maximum relative modulation level. Override the maximum relative modulation from the thermostat. Valid values are 0 through 100. Clear the setting by specifying a non-numeric value. This method supports the following arguments:

Returns the newly accepted value, - if a previous value was cleared, or None on failure.

This method is a coroutine.

Set the operating mode of the gateway.

The operating mode can be either gateway or monitor mode. This method can also be used to reset the OpenTherm Gateway.

This method supports the following arguments:

0 or OTGW_MODE_MONITOR for monitor mode, 1 or OTGW_MODE_GATEWAY for gateway mode, or OTGW_MODE_RESET` to reset the gateway.Return the newly activated mode, or the full renewed status dict after a reset.

This method is a coroutine.

Set the outside temperature. Configure the outside temperature to send to the thermostat. Allowed values are between -40.0 and +64.0, although thermostats may not display the full range. Specify a value above 64 (suggestion: 99) to clear a previously configured value. This method supports the following arguments:

Returns the accepted value on success, - if a previously configured value has been cleared or None on failure.

This method is a coroutine.

Set the setback temperature.

Configure the setback temperature to use in combination with the GPIO functions home(5) and away(6).

This method supports the following arguments:

Returns the new setback temperature, or None on failure.

This method is a coroutine.

Set the room setpoint. Configure the thermostat setpoint and specify whether or not it may be overridden by a programmed change. This method supports the following arguments:

True or False. Defaults to True.Returns the newly accepted room setpoint, or None on failure.

This method is a coroutine.

Set the function of the temperature sensor that can be attached to the gateway. This method supports the following arguments:

O for Outside Air Temperature or R for Return Water Temperature.Returns the newly accepted temperature sensor function or None on failure.

This method is a coroutine.

Set the ventilation setpoint. Configure a ventilation setpoint override value (0-100%). This method supports the following arguments:

0 and 100.Return the newly accepted value, or None on failure.

This method is a coroutine.

Send a transparent command. Sends custom commands through a transparent interface. Check https://otgw.tclcode.com/firmware.html for supported commands. This method supports the following arguments:

SC (set time/day).23:59/4 (the current time/day)Returns the gateway response, which should be equal state.

This method is a coroutine.

Subscribe to status updates from the Opentherm Gateway. The subscribed coroutine must have the following signature:

async def coro(status)

Where status will be the full status dict containing the last known information from the OpenTherm Gateway.

This method supports the following arguments:

Returns True on success, False if the coroutine is already subscribed.

Unsubscribe from status updates from the Opentherm Gateway.

The supplied coroutine must have been subscribed with OpenThermGateway.subscribe() before.

This method supports the following arguments:

Returns True on success, False if the coroutine was not subscribed before.

import asyncio

from pyotgw import OpenThermGateway

PORT = '/dev/ttyUSB0'

async def print_status(status):

"""Receive and print status."""

print("Received a status update:\n{}".format(status))

async def connect_and_subscribe():

"""Connect to the OpenTherm Gateway and subscribe to status updates."""

# Create the object

gw = OpenThermGateway()

# Connect to OpenTherm Gateway on PORT

status = await gw.connect(PORT)

print("Initial status after connecting:\n{}".format(status))

# Subscribe to updates from the gateway

if not gw.subscribe(print_status):

print("Could not subscribe to status updates.")

# Keep the event loop alive...

while True:

await asyncio.sleep(1)

# Run the connect_and_subscribe coroutine.

try:

asyncio.run(connect_and_subscribe())

except KeyboardInterrupt:

print("Exiting")

We use pre-commit to ensure a consistent code style, so pip install pre_commit and run

pre-commit install

in the repository.

The full possible status dict with some example values looks like below. Note that not all keys will always be present and that the presence of a key does not guarantee that it contains useful information.

{

vars.BOILER: {

vars.DATA_CH_PUMP_HOURS: 15010,

vars.DATA_CH_PUMP_STARTS: 43832,

vars.DATA_CH_WATER_PRESS: 0.0,

vars.DATA_CH_WATER_TEMP: 47.2,

vars.DATA_CH_WATER_TEMP_2: 0.0,

vars.DATA_CONTROL_SETPOINT: 44.0,

vars.DATA_CONTROL_SETPOINT_2: 0.0,

vars.DATA_COOLING_CONTROL: 0,

vars.DATA_DHW_BURNER_HOURS: 411,

vars.DATA_DHW_BURNER_STARTS: 34296,

vars.DATA_DHW_FLOW_RATE: 0.0,

vars.DATA_DHW_PUMP_HOURS: 250,

vars.DATA_DHW_PUMP_STARTS: 9424,

vars.DATA_DHW_SETPOINT: 0.0,

vars.DATA_DHW_TEMP: 0.0,

vars.DATA_DHW_TEMP_2: 0.0,

vars.DATA_EXHAUST_TEMP: 0,

vars.DATA_MASTER_CH2_ENABLED: 0,

vars.DATA_MASTER_CH_ENABLED: 1,

vars.DATA_MASTER_COOLING_ENABLED: 0,

vars.DATA_MASTER_DHW_ENABLED: 1,

vars.DATA_MASTER_MEMBERID: 0,

vars.DATA_MASTER_OTC_ENABLED: 0,

vars.DATA_MASTER_OT_VERSION: 0.0,

vars.DATA_MASTER_PRODUCT_TYPE: 0,

vars.DATA_MASTER_PRODUCT_VERSION: 0,

vars.DATA_MAX_CH_SETPOINT: 75.0,

vars.DATA_OEM_DIAG: 0,

vars.DATA_OUTSIDE_TEMP: 0.0,

vars.DATA_REL_MOD_LEVEL: 0.0,

vars.DATA_REMOTE_RW_DHW: 1,

vars.DATA_REMOTE_RW_MAX_CH: 1,

vars.DATA_REMOTE_TRANSFER_DHW: 1,

vars.DATA_REMOTE_TRANSFER_MAX_CH: 1,

vars.DATA_RETURN_WATER_TEMP: 0.0,

vars.DATA_ROOM_SETPOINT: 20.0,

vars.DATA_ROOM_SETPOINT_2: 0.0,

vars.DATA_ROOM_SETPOINT_OVRD: 20.0,

vars.DATA_ROOM_TEMP: 19.62,

vars.DATA_ROVRD_AUTO_PRIO: 0,

vars.DATA_ROVRD_MAN_PRIO: 1,

vars.DATA_SLAVE_AIR_PRESS_FAULT: 0,

vars.DATA_SLAVE_CH2_ACTIVE: 0,

vars.DATA_SLAVE_CH2_PRESENT: 0,

vars.DATA_SLAVE_CH_ACTIVE: 1,

vars.DATA_SLAVE_CH_MAX_SETP: 75,

vars.DATA_SLAVE_CH_MIN_SETP: 20,

vars.DATA_SLAVE_CONTROL_TYPE: 1,

vars.DATA_SLAVE_COOLING_ACTIVE: 0,

vars.DATA_SLAVE_COOLING_SUPPORTED: 0,

vars.DATA_SLAVE_DHW_ACTIVE: 0,

vars.DATA_SLAVE_DHW_CONFIG: 0,

vars.DATA_SLAVE_DHW_MAX_SETP: 60,

vars.DATA_SLAVE_DHW_MIN_SETP: 40,

vars.DATA_SLAVE_DHW_PRESENT: 1,

vars.DATA_SLAVE_DIAG_IND: 0,

vars.DATA_SLAVE_FAULT_IND: 0,

vars.DATA_SLAVE_FLAME_ON: 1,

vars.DATA_SLAVE_GAS_FAULT: 0,

vars.DATA_SLAVE_LOW_WATER_PRESS: 0,

vars.DATA_SLAVE_MASTER_LOW_OFF_PUMP: 0,

vars.DATA_SLAVE_MAX_CAPACITY: 0,

vars.DATA_SLAVE_MAX_RELATIVE_MOD: 100.0,

vars.DATA_SLAVE_MEMBERID: 0,

vars.DATA_SLAVE_MIN_MOD_LEVEL: 0,

vars.DATA_SLAVE_OEM_FAULT: 0,

vars.DATA_SLAVE_OT_VERSION: 0.0,

vars.DATA_SLAVE_PRODUCT_TYPE: 0,

vars.DATA_SLAVE_PRODUCT_VERSION: 0,

vars.DATA_SLAVE_REMOTE_RESET: 0,

vars.DATA_SLAVE_SERVICE_REQ: 0,

vars.DATA_SLAVE_WATER_OVERTEMP: 0,

vars.DATA_SOLAR_COLL_TEMP: 0.0,

vars.DATA_SOLAR_STORAGE_TEMP: 0.0,

vars.DATA_TOTAL_BURNER_HOURS: 0,

vars.DATA_TOTAL_BURNER_STARTS: 0,

},

vars.OTGW: {

vars.OTGW_ABOUT: 'OpenTherm Gateway 4.2.5',

vars.OTGW_BUILD: '17:59 20-10-2015',

vars.OTGW_CLOCKMHZ: '4 MHz',

vars.OTGW_DHW_OVRD: '1',

vars.OTGW_GPIO_A: 0,

vars.OTGW_GPIO_A_STATE: 0,

vars.OTGW_GPIO_B: 0,

vars.OTGW_GPIO_B_STATE: 0,

vars.OTGW_IGNORE_TRANSITIONS: 1,

vars.OTGW_LED_A: 'F',

vars.OTGW_LED_B: 'X',

vars.OTGW_LED_C: 'O',

vars.OTGW_LED_D: 'M',

vars.OTGW_LED_E: 'P',

vars.OTGW_LED_F: 'C',

vars.OTGW_MODE: 'G',

vars.OTGW_OVRD_HB: 1,

vars.OTGW_SB_TEMP: 16.0,

vars.OTGW_SETP_OVRD_MODE: 'T',

vars.OTGW_SMART_PWR: 'Low power',

vars.OTGW_THRM_DETECT: 'D',

vars.OTGW_VREF: 3,

},

vars.THERMOSTAT: {

vars.DATA_CH_PUMP_HOURS: 15010,

vars.DATA_CH_PUMP_STARTS: 43832,

vars.DATA_CH_WATER_PRESS: 0.0,

vars.DATA_CH_WATER_TEMP: 47.2,

vars.DATA_CH_WATER_TEMP_2: 0.0,

vars.DATA_CONTROL_SETPOINT: 44.0,

vars.DATA_CONTROL_SETPOINT_2: 0.0,

vars.DATA_COOLING_CONTROL: 0,

vars.DATA_DHW_BURNER_HOURS: 411,

vars.DATA_DHW_BURNER_STARTS: 34296,

vars.DATA_DHW_FLOW_RATE: 0.0,

vars.DATA_DHW_PUMP_HOURS: 250,

vars.DATA_DHW_PUMP_STARTS: 9424,

vars.DATA_DHW_SETPOINT: 0.0,

vars.DATA_DHW_TEMP: 0.0,

vars.DATA_DHW_TEMP_2: 0.0,

vars.DATA_EXHAUST_TEMP: 0,

vars.DATA_MASTER_CH2_ENABLED: 0,

vars.DATA_MASTER_CH_ENABLED: 1,

vars.DATA_MASTER_COOLING_ENABLED: 0,

vars.DATA_MASTER_DHW_ENABLED: 1,

vars.DATA_MASTER_MEMBERID: 0,

vars.DATA_MASTER_OTC_ENABLED: 0,

vars.DATA_MASTER_OT_VERSION: 0.0,

vars.DATA_MASTER_PRODUCT_TYPE: 0,

vars.DATA_MASTER_PRODUCT_VERSION: 0,

vars.DATA_MAX_CH_SETPOINT: 75.0,

vars.DATA_OEM_DIAG: 0,

vars.DATA_OUTSIDE_TEMP: 0.0,

vars.DATA_REL_MOD_LEVEL: 0.0,

vars.DATA_REMOTE_RW_DHW: 1,

vars.DATA_REMOTE_RW_MAX_CH: 1,

vars.DATA_REMOTE_TRANSFER_DHW: 1,

vars.DATA_REMOTE_TRANSFER_MAX_CH: 1,

vars.DATA_RETURN_WATER_TEMP: 0.0,

vars.DATA_ROOM_SETPOINT: 20.0,

vars.DATA_ROOM_SETPOINT_2: 0.0,

vars.DATA_ROOM_SETPOINT_OVRD: 20.0,

vars.DATA_ROOM_TEMP: 19.62,

vars.DATA_ROVRD_AUTO_PRIO: 0,

vars.DATA_ROVRD_MAN_PRIO: 1,

vars.DATA_SLAVE_AIR_PRESS_FAULT: 0,

vars.DATA_SLAVE_CH2_ACTIVE: 0,

vars.DATA_SLAVE_CH2_PRESENT: 0,

vars.DATA_SLAVE_CH_ACTIVE: 1,

vars.DATA_SLAVE_CH_MAX_SETP: 75,

vars.DATA_SLAVE_CH_MIN_SETP: 20,

vars.DATA_SLAVE_CONTROL_TYPE: 1,

vars.DATA_SLAVE_COOLING_ACTIVE: 0,

vars.DATA_SLAVE_COOLING_SUPPORTED: 0,

vars.DATA_SLAVE_DHW_ACTIVE: 0,

vars.DATA_SLAVE_DHW_CONFIG: 0,

vars.DATA_SLAVE_DHW_MAX_SETP: 60,

vars.DATA_SLAVE_DHW_MIN_SETP: 40,

vars.DATA_SLAVE_DHW_PRESENT: 1,

vars.DATA_SLAVE_DIAG_IND: 0,

vars.DATA_SLAVE_FAULT_IND: 0,

vars.DATA_SLAVE_FLAME_ON: 1,

vars.DATA_SLAVE_GAS_FAULT: 0,

vars.DATA_SLAVE_LOW_WATER_PRESS: 0,

vars.DATA_SLAVE_MASTER_LOW_OFF_PUMP: 0,

vars.DATA_SLAVE_MAX_CAPACITY: 0,

vars.DATA_SLAVE_MAX_RELATIVE_MOD: 100.0,

vars.DATA_SLAVE_MEMBERID: 0,

vars.DATA_SLAVE_MIN_MOD_LEVEL: 0,

vars.DATA_SLAVE_OEM_FAULT: 0,

vars.DATA_SLAVE_OT_VERSION: 0.0,

vars.DATA_SLAVE_PRODUCT_TYPE: 0,

vars.DATA_SLAVE_PRODUCT_VERSION: 0,

vars.DATA_SLAVE_REMOTE_RESET: 0,

vars.DATA_SLAVE_SERVICE_REQ: 0,

vars.DATA_SLAVE_WATER_OVERTEMP: 0,

vars.DATA_SOLAR_COLL_TEMP: 0.0,

vars.DATA_SOLAR_STORAGE_TEMP: 0.0,

vars.DATA_TOTAL_BURNER_HOURS: 0,

vars.DATA_TOTAL_BURNER_STARTS: 0,

}

}

FAQs

A library to interface with the opentherm gateway through serial or network connection.

We found that pyotgw demonstrated a healthy version release cadence and project activity because the last version was released less than a year ago. It has 1 open source maintainer collaborating on the project.

Did you know?

Socket for GitHub automatically highlights issues in each pull request and monitors the health of all your open source dependencies. Discover the contents of your packages and block harmful activity before you install or update your dependencies.

Security News

Research

The Socket Research Team breaks down a malicious wrapper package that uses obfuscation to harvest credentials and exfiltrate sensitive data.

Research

Security News

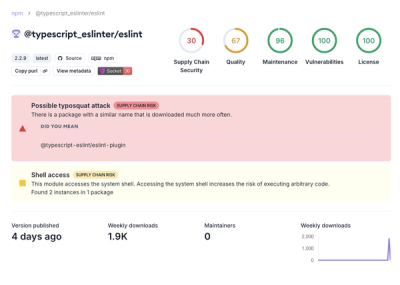

Attackers used a malicious npm package typosquatting a popular ESLint plugin to steal sensitive data, execute commands, and exploit developer systems.

Security News

The Ultralytics' PyPI Package was compromised four times in one weekend through GitHub Actions cache poisoning and failure to rotate previously compromised API tokens.